- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

FL series

Hambition / Fambition

FAMBITION series LHD is designed, manufactured and tested in strict accordance with ISO9001, ISO14001, CE-MD standards, following safety, environmental protection, efficient, inteligent and reliable design concepts. It has features of high efficiency in shovel loading, low maintenance cost strong power and strong shoveling capacity.

Feature:

Hydraulic system is specially design for Solidwork, using steel pipe, which can save maintenance cost;

Special design of running control system, it will control the suspension of the boom using hydraulic energy storage (optional).

Running system:

Boom system:

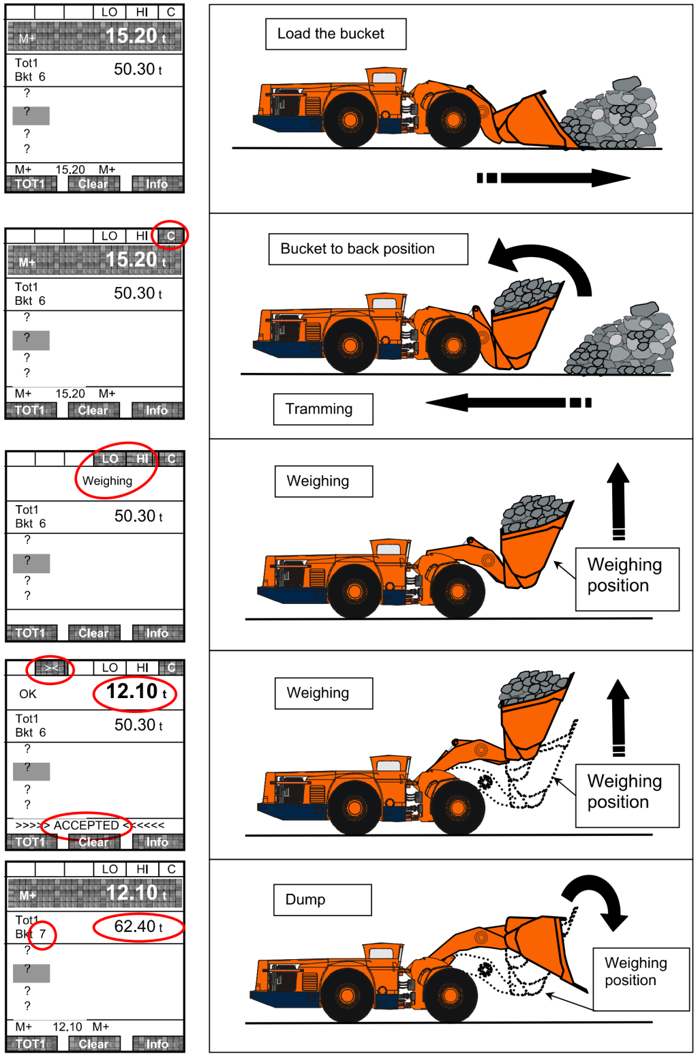

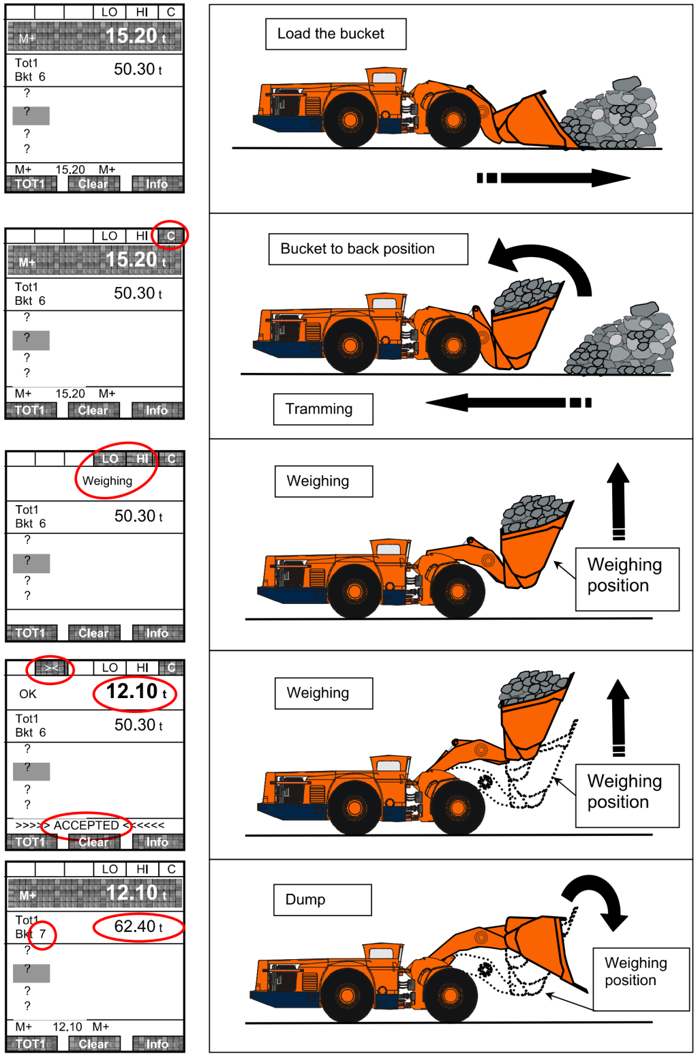

3. Weighing system (optional)

4. CAN-Bus system for central control, no extra fee.

FAMBITION series LHD is designed, manufactured and tested in strict accordance with ISO9001, ISO14001, CE-MD standards, following safety, environmental protection, efficient, inteligent and reliable design concepts. It has features of high efficiency in shovel loading, low maintenance cost strong power and strong shoveling capacity.

Feature:

Hydraulic system is specially design for Solidwork, using steel pipe, which can save maintenance cost;

Special design of running control system, it will control the suspension of the boom using hydraulic energy storage (optional).

Running system:

Boom system:

3. Weighing system (optional)

4. CAN-Bus system for central control, no extra fee.

Type 1: FL14E ——14MT 6m³ Electric power

FL14E is an electric LHD designed for large scale underground metal mines production, payload 14MT. FL14E has a horizontal cable reeling system that enables the loader to pass power supply box without turning and can travel flexibly. The electric cabinet could protect personnel and equipment from all electricity danger. Trailing system gives an easier transfer between different stopes. FL14E has an EHC variable hydraulic system and constant tension sensing cable-reel control system. The on board display could show real time operating parameters and state, including self-diagnostics. Standard stadia remote control system, auto lubrication system and Ansul auto fire suppression system are optional for the loader. FL14E is an optimized loader- haul solution to large scale mining.

Specification

Performance | Power System | Drivetrain system |

St bucket capacity: 6m³ | Main motor: Vem IE3-W41R 315, 132KW, 1500rpm, 1000V, 50HZ | Torque converter: DANA C8000 |

Rated payload: 14,000 kg | Pump motor: Vem IE3-Y41R 225, 45KW, 1482rpm, 900V, 50HZ | Transmission: DANA 6000 |

Operating weight: 39,000 kg | Fam motor: 2*1.5KW | Axle: Kessler D 106 |

Breakout force:246 KN | Brake: Posi-Stop wheel brake | |

Traction force: 240 KN | Tire model: 26.5-25 | |

Cable reeling system | Cabin | Option |

Cable: 330m, 4*50 mm2 | Enclosed cabin with air conditioner | Bucket: 4.6~7.0 m³ |

Type: horizontal cable reeler electric cabinet (IT) | FOPS/ ROPS Certified | Lincoln auto lubrication system |

Others: cable anchor, cable cushion, plug | Manual central lubrication | Ansul auto fire suppression system |

Trailing: on board trailing system, trailing bar | ||

Dimension | Hydraulic system | Control system |

Length: 11,073 mm | Hydraulic pump: KPM | FET electronic technician |

Width: 2783mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2552 mm | Working valve: Parker | 5.7” color display |

Ground clearance: 386 mm | Steering valve: Parker | 3 modular design |

Dump height: 2406 mm | Hydraulic oil tank volume | |

Steering angle: ±42.5° | Work & Steer tank: 320L | Trouble alarm |

Inner turning radius: 3293mm | Brake tank: 70L | Self-diagnosis |

Out turning radius: 6932mm | Data log download | |

Type 2: FL14 ——14MT 6m³ Diesel power

FL14 is a diesel engine LHD designed for large scale underground metal mines production, payload 14MT. All key components are international well-known brands, the vehicle adopts hydraulic pilot control and EHC variable hydraulic system. The control system based on CAN-bus technology, Fambition Electronic Technician, with on board display to show real time operating parameters with self-diagnostic and troubleshooting. Standard visual remote control system, auto lubrication system and Ansul auto fire suppression system are optional for the loader.

Specification

Performance | Power System | Drivetrain system |

St bucket capacity: 6m³ | Main motor: Volvo TAD1350VE | Torque converter: DANA C9000 |

Rated payload: 14,000 kg | Power: 256KW@1900rpm | Transmission: DANA 6000 |

Operating weight: 39,000 kg | Torque: 1780NM@1260rpm | Axle: Kessler D 106 |

Breakout force:246 KN | Type: EFI, water cooled, Turbo charged | Brake: Posi-Stop wheel brake |

Traction force: 324 KN | Emission: Tier 3 Stage III | Tire model: 26.5-25 |

Others | Cabin | Option |

Manual central lubrication, fire extinguisher | Enclosed cabin with air conditioner | Bucket: 4.6~7.0 m³ |

Boom lock pin, articulation pin, revers alarm | FOPS/ ROPS Certified | Lincoln auto lubrication system |

Door interlock | Ansul auto fire suppression system | |

Double joystick control | Radio remote control device | |

LED front and rear lights | ||

Dimension | Hydraulic system | Control system |

Length: 10,641 mm | Hydraulic pump: Rexroth | FET electronic technician |

Width: 2793mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2552 mm | Working valve: Rexroth, Parker, Mico | 5.7” color display |

Ground clearance: 386 mm | Fuel tank: 420L | 3 modular design |

Dump height: 2406 mm | Hydraulic oil tank volume | |

Steering angle: ±42.5° | Work & Steer tank: 230L | Alarm warning |

Inner turning radius: 3283mm | Brake tank: 75L | Self-diagnosis |

Out turning radius: 6932mm | Cooler: engine, transmission oil, hydraulic oil | Data log download |

Type 1: FL14E ——14MT 6m³ Electric power

FL14E is an electric LHD designed for large scale underground metal mines production, payload 14MT. FL14E has a horizontal cable reeling system that enables the loader to pass power supply box without turning and can travel flexibly. The electric cabinet could protect personnel and equipment from all electricity danger. Trailing system gives an easier transfer between different stopes. FL14E has an EHC variable hydraulic system and constant tension sensing cable-reel control system. The on board display could show real time operating parameters and state, including self-diagnostics. Standard stadia remote control system, auto lubrication system and Ansul auto fire suppression system are optional for the loader. FL14E is an optimized loader- haul solution to large scale mining.

Specification

Performance | Power System | Drivetrain system |

St bucket capacity: 6m³ | Main motor: Vem IE3-W41R 315, 132KW, 1500rpm, 1000V, 50HZ | Torque converter: DANA C8000 |

Rated payload: 14,000 kg | Pump motor: Vem IE3-Y41R 225, 45KW, 1482rpm, 900V, 50HZ | Transmission: DANA 6000 |

Operating weight: 39,000 kg | Fam motor: 2*1.5KW | Axle: Kessler D 106 |

Breakout force:246 KN | Brake: Posi-Stop wheel brake | |

Traction force: 240 KN | Tire model: 26.5-25 | |

Cable reeling system | Cabin | Option |

Cable: 330m, 4*50 mm2 | Enclosed cabin with air conditioner | Bucket: 4.6~7.0 m³ |

Type: horizontal cable reeler electric cabinet (IT) | FOPS/ ROPS Certified | Lincoln auto lubrication system |

Others: cable anchor, cable cushion, plug | Manual central lubrication | Ansul auto fire suppression system |

Trailing: on board trailing system, trailing bar | ||

Dimension | Hydraulic system | Control system |

Length: 11,073 mm | Hydraulic pump: KPM | FET electronic technician |

Width: 2783mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2552 mm | Working valve: Parker | 5.7” color display |

Ground clearance: 386 mm | Steering valve: Parker | 3 modular design |

Dump height: 2406 mm | Hydraulic oil tank volume | |

Steering angle: ±42.5° | Work & Steer tank: 320L | Trouble alarm |

Inner turning radius: 3293mm | Brake tank: 70L | Self-diagnosis |

Out turning radius: 6932mm | Data log download | |

Type 2: FL14 ——14MT 6m³ Diesel power

FL14 is a diesel engine LHD designed for large scale underground metal mines production, payload 14MT. All key components are international well-known brands, the vehicle adopts hydraulic pilot control and EHC variable hydraulic system. The control system based on CAN-bus technology, Fambition Electronic Technician, with on board display to show real time operating parameters with self-diagnostic and troubleshooting. Standard visual remote control system, auto lubrication system and Ansul auto fire suppression system are optional for the loader.

Specification

Performance | Power System | Drivetrain system |

St bucket capacity: 6m³ | Main motor: Volvo TAD1350VE | Torque converter: DANA C9000 |

Rated payload: 14,000 kg | Power: 256KW@1900rpm | Transmission: DANA 6000 |

Operating weight: 39,000 kg | Torque: 1780NM@1260rpm | Axle: Kessler D 106 |

Breakout force:246 KN | Type: EFI, water cooled, Turbo charged | Brake: Posi-Stop wheel brake |

Traction force: 324 KN | Emission: Tier 3 Stage III | Tire model: 26.5-25 |

Others | Cabin | Option |

Manual central lubrication, fire extinguisher | Enclosed cabin with air conditioner | Bucket: 4.6~7.0 m³ |

Boom lock pin, articulation pin, revers alarm | FOPS/ ROPS Certified | Lincoln auto lubrication system |

Door interlock | Ansul auto fire suppression system | |

Double joystick control | Radio remote control device | |

LED front and rear lights | ||

Dimension | Hydraulic system | Control system |

Length: 10,641 mm | Hydraulic pump: Rexroth | FET electronic technician |

Width: 2793mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2552 mm | Working valve: Rexroth, Parker, Mico | 5.7” color display |

Ground clearance: 386 mm | Fuel tank: 420L | 3 modular design |

Dump height: 2406 mm | Hydraulic oil tank volume | |

Steering angle: ±42.5° | Work & Steer tank: 230L | Alarm warning |

Inner turning radius: 3283mm | Brake tank: 75L | Self-diagnosis |

Out turning radius: 6932mm | Cooler: engine, transmission oil, hydraulic oil | Data log download |

Type 1: FL10E ——10MT 4m³ Electric power

FL10E is an electric LHD designed for medium and large scale underground metal mines, payload 10 metric tons. FL10E equipped with horizontal reel system that enables the LHD pass the junction box without a U-Tum. It makes driving simple and flexible. The power cabinet on the LHD can protect the personnel and equipment from all electric danger. The towing system allows the LHD to move easily and safely. The FL10E LHD is equipped with an electro- hydraulic controlled variable hydraulic system, and an constant tension induction automatic control cable-reel system. The on-board display screen can display the operating parameters of the LHD in real time and has a self-diagnosis function. Equipped with standard visible radio remote control system, options are automatic centralized lubrication system and Ansul centralized fire protection system.

Specification

Performance | Power System | Drivetrain system |

St bucket capacity: 4m³ | Main motor: VEM IE3-W41R 110KW, 1487rpm, 1000V, 50Hz | Torque converter: DANA C5000 |

Rated payload: 10,000 kg | Pump motor: VEM IE3-Y41R 45KW, 1482rpm, 900V, 50Hz | Transmission: DANA R36000 |

Operating weight: 29,000 kg | Fan motor: 2*15KW | Axle: Kessler D 102 |

Breakout force: 188 KN | Brake: Posi-Stop wheel brake | |

Traction force: 220 KN | Tire model: 18.00-25 | |

Cable reeling system | Cabin | Option |

Cable: 330m, 3*35mm2+1*25mm2 | Enclosed cabin with air conditioner | Bucket: 4.0~5.4 m³ |

Type: horizontal cable reeler | FOPS/ ROPS Certified | Lincoln auto lubrication system |

Electric cabinet (IT) | Manual central lubrication | Ansul auto fire suppression system |

Others: cable anchor, cable cushion, plug | ||

Drailing: onboard trailing system, trailing bar | ||

Dimension | Hydraulic system | Control system |

Length: 10,949 mm | Hydraulic pump: KPM | FET electronic technician |

Width: 2530mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2385 mm | Working valve: Parker | 5.7” color display |

Ground clearance: 380 mm | Steering valve: Parker | 3 modular design |

Dump height: 1914 mm | Hydraulic oil tank volume | Radio remote control device |

Steering angle: ±42.5° | Work & Steer tank: 300L | Trouble alarm |

Inner turning radius: 3211mm | Brake tank: 75L | Self-diagnosis |

Out turning radius: 6502mm | Data log download | |

Type 2 : FL10 ——10MT 4m³ Diesel power

FL10 is a diesel engine LHD designed for large scale underground metal mines production, payload 10 MT. All key components are international well-known brands, the vehicle adopts hydraulic pilot control and EHC variable hydraulic system. The control system based on CAN-bus technology. Fambition Electronic Technician, with on board display to show real time operating parameters with self-diagnostic and troubleshooting. Standard visual remote control system, auto lubrication system and Ansul auto fire suppression system are optional for the loader. The design and manufacturing of FL10 is in the first class of the industry, higher production capability, lower downtime and lower operating cost.

Specification

Performance | Engine | Drivetrain system |

St bucket capacity: 4m³ | Model: Volvo TAD853VE | Torque converter: DANA C5000 |

Rated payload: 10,000 kg | Power: 235KW @ 2200rpm | Transmission: DANA R36000 |

Operating weight: 29,000 kg | Torque: 1064Nm @ 1500 rpm | Axle: Kessler D 102 |

Breakout force: 188 KN | Type: EFI, water cooled, turo charged | Brake: Posi-Stop wheel brake |

Traction force: 220 KN | Emission: Tier 3 Stage III | Tire model: 18.00-25 |

Others | Cabin | Option |

Manual central lubrication system fire extinguisher | Enclosed cabin with air conditioner | Bucket: 4.0~5.4 m³ |

Boom bolt/ hinge bolt/ reverse alarm | FOPS/ ROPS Certified | SKF central automatic lubrication system |

Door interlock protection | Ansul auto fire suppression system | |

Double joystick control | Mercedes EFL diesel engine | |

LED front and rear lights | Radio remote control device | |

Dimension | Hydraulic system | Control system |

Length: 9777 mm | Hydraulic pump: Rexroth | FET electronic technician |

Width: 2602 mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2385 mm | Hydraulic valve: Rexroth, Parker, Mico | 5.7” color display |

Ground clearance: 380 mm | Hydraulic oil tank volume | 3 modular design |

Dump height: 1914 mm | Work & Steer : 240L | |

Steering angle: ±42.5° | Brake tank: 57L | Trouble alarm |

Inner turning radius: 3211mm | Fuel tank: 310L | Self-diagnosis |

Out turning radius: 6502mm | Cooler: engine, transmission oil, hydraulic oil | Data log download |

Type 1: FL10E ——10MT 4m³ Electric power

FL10E is an electric LHD designed for medium and large scale underground metal mines, payload 10 metric tons. FL10E equipped with horizontal reel system that enables the LHD pass the junction box without a U-Tum. It makes driving simple and flexible. The power cabinet on the LHD can protect the personnel and equipment from all electric danger. The towing system allows the LHD to move easily and safely. The FL10E LHD is equipped with an electro- hydraulic controlled variable hydraulic system, and an constant tension induction automatic control cable-reel system. The on-board display screen can display the operating parameters of the LHD in real time and has a self-diagnosis function. Equipped with standard visible radio remote control system, options are automatic centralized lubrication system and Ansul centralized fire protection system.

Specification

Performance | Power System | Drivetrain system |

St bucket capacity: 4m³ | Main motor: VEM IE3-W41R 110KW, 1487rpm, 1000V, 50Hz | Torque converter: DANA C5000 |

Rated payload: 10,000 kg | Pump motor: VEM IE3-Y41R 45KW, 1482rpm, 900V, 50Hz | Transmission: DANA R36000 |

Operating weight: 29,000 kg | Fan motor: 2*15KW | Axle: Kessler D 102 |

Breakout force: 188 KN | Brake: Posi-Stop wheel brake | |

Traction force: 220 KN | Tire model: 18.00-25 | |

Cable reeling system | Cabin | Option |

Cable: 330m, 3*35mm2+1*25mm2 | Enclosed cabin with air conditioner | Bucket: 4.0~5.4 m³ |

Type: horizontal cable reeler | FOPS/ ROPS Certified | Lincoln auto lubrication system |

Electric cabinet (IT) | Manual central lubrication | Ansul auto fire suppression system |

Others: cable anchor, cable cushion, plug | ||

Drailing: onboard trailing system, trailing bar | ||

Dimension | Hydraulic system | Control system |

Length: 10,949 mm | Hydraulic pump: KPM | FET electronic technician |

Width: 2530mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2385 mm | Working valve: Parker | 5.7” color display |

Ground clearance: 380 mm | Steering valve: Parker | 3 modular design |

Dump height: 1914 mm | Hydraulic oil tank volume | Radio remote control device |

Steering angle: ±42.5° | Work & Steer tank: 300L | Trouble alarm |

Inner turning radius: 3211mm | Brake tank: 75L | Self-diagnosis |

Out turning radius: 6502mm | Data log download | |

Type 2 : FL10 ——10MT 4m³ Diesel power

FL10 is a diesel engine LHD designed for large scale underground metal mines production, payload 10 MT. All key components are international well-known brands, the vehicle adopts hydraulic pilot control and EHC variable hydraulic system. The control system based on CAN-bus technology. Fambition Electronic Technician, with on board display to show real time operating parameters with self-diagnostic and troubleshooting. Standard visual remote control system, auto lubrication system and Ansul auto fire suppression system are optional for the loader. The design and manufacturing of FL10 is in the first class of the industry, higher production capability, lower downtime and lower operating cost.

Specification

Performance | Engine | Drivetrain system |

St bucket capacity: 4m³ | Model: Volvo TAD853VE | Torque converter: DANA C5000 |

Rated payload: 10,000 kg | Power: 235KW @ 2200rpm | Transmission: DANA R36000 |

Operating weight: 29,000 kg | Torque: 1064Nm @ 1500 rpm | Axle: Kessler D 102 |

Breakout force: 188 KN | Type: EFI, water cooled, turo charged | Brake: Posi-Stop wheel brake |

Traction force: 220 KN | Emission: Tier 3 Stage III | Tire model: 18.00-25 |

Others | Cabin | Option |

Manual central lubrication system fire extinguisher | Enclosed cabin with air conditioner | Bucket: 4.0~5.4 m³ |

Boom bolt/ hinge bolt/ reverse alarm | FOPS/ ROPS Certified | SKF central automatic lubrication system |

Door interlock protection | Ansul auto fire suppression system | |

Double joystick control | Mercedes EFL diesel engine | |

LED front and rear lights | Radio remote control device | |

Dimension | Hydraulic system | Control system |

Length: 9777 mm | Hydraulic pump: Rexroth | FET electronic technician |

Width: 2602 mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2385 mm | Hydraulic valve: Rexroth, Parker, Mico | 5.7” color display |

Ground clearance: 380 mm | Hydraulic oil tank volume | 3 modular design |

Dump height: 1914 mm | Work & Steer : 240L | |

Steering angle: ±42.5° | Brake tank: 57L | Trouble alarm |

Inner turning radius: 3211mm | Fuel tank: 310L | Self-diagnosis |

Out turning radius: 6502mm | Cooler: engine, transmission oil, hydraulic oil | Data log download |

FL07 ——7MT 3m³ Diesel power

FL07 is a 7-ton diesel LHD designed for medium underground metal mines. The main parts of FL07 use international famous brand, the whole vehicle control system adopts CAN-bus communication technology. Fambition Electronic Technician, electro-hydraulic proportional pilot control and variable hydraulic system. The control system is designed on the basis of CAN-bus. The on-board display screen can display the operating parameters of the scraper in real time, and has the functions of fault warning and self-diagnosis. Optional automatic central lubrication system and Ansul automatic fire extinguishing system. The design and manufacture of FL07 have reached the advanced level of the industry, the production capacity is high, the failure rate is low, the use cost is low.

Specification

Performance | Engine | Drivetrain system |

St bucket capacity: 3m³ | Model: Volvo TAD850VE | Torque converter: DANA C270 |

Rated payload: 7,000 kg | Power: 160KW @ 2200rpm | Transmission: DANA R32000 |

Operating weight: 18500 kg | Torque: 1060Nm @ 1500 rpm | Axle: Kessler D 91/ DANA 16D |

Breakout force: 134 KN | Type: EFI, water cooled, turo charged | Brake: Posi-Stop wheel brake |

Traction force: 156 KN | Emission: Tier 3 Stage III | Tire model: 17.5-25 |

Others | Cabin | Option |

Manual central lubrication system fire extinguisher | Enclosed cabin with air conditioner | SKF automatic lubrication system |

Boom bolt/ hinge bolt/ reverse alarm | FOPS/ ROPS Certified | Ansul auto fire suppression system |

Door interlock protection | Radio remote control device | |

Double joystick control | ||

LED front and rear lights | ||

Dimension | Hydraulic system | Control system |

Length: 8765 mm | Hydraulic pump: Rexroth | FET electronic technician |

Width: 2256 mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2217 mm | Hydraulic valve: Rexroth, Parker, Mico | 5.7” color display |

Ground clearance: 286 mm | Fuel tank capacity | 3 modular design |

Dump height: 1826 mm | Hydraulic oil tank: 230L | |

Steering angle: ±42.5° | Fuel tank: 210L | Trouble alarm |

Inner turning radius: 2814mm | Cooler: engine, transmission oil, hydraulic oil | Self-diagnosis |

Out turning radius: 5809mm | Data log download | |

FL07 ——7MT 3m³ Diesel power

FL07 is a 7-ton diesel LHD designed for medium underground metal mines. The main parts of FL07 use international famous brand, the whole vehicle control system adopts CAN-bus communication technology. Fambition Electronic Technician, electro-hydraulic proportional pilot control and variable hydraulic system. The control system is designed on the basis of CAN-bus. The on-board display screen can display the operating parameters of the scraper in real time, and has the functions of fault warning and self-diagnosis. Optional automatic central lubrication system and Ansul automatic fire extinguishing system. The design and manufacture of FL07 have reached the advanced level of the industry, the production capacity is high, the failure rate is low, the use cost is low.

Specification

Performance | Engine | Drivetrain system |

St bucket capacity: 3m³ | Model: Volvo TAD850VE | Torque converter: DANA C270 |

Rated payload: 7,000 kg | Power: 160KW @ 2200rpm | Transmission: DANA R32000 |

Operating weight: 18500 kg | Torque: 1060Nm @ 1500 rpm | Axle: Kessler D 91/ DANA 16D |

Breakout force: 134 KN | Type: EFI, water cooled, turo charged | Brake: Posi-Stop wheel brake |

Traction force: 156 KN | Emission: Tier 3 Stage III | Tire model: 17.5-25 |

Others | Cabin | Option |

Manual central lubrication system fire extinguisher | Enclosed cabin with air conditioner | SKF automatic lubrication system |

Boom bolt/ hinge bolt/ reverse alarm | FOPS/ ROPS Certified | Ansul auto fire suppression system |

Door interlock protection | Radio remote control device | |

Double joystick control | ||

LED front and rear lights | ||

Dimension | Hydraulic system | Control system |

Length: 8765 mm | Hydraulic pump: Rexroth | FET electronic technician |

Width: 2256 mm(cabin included) | Load sensing variable plunger double pump | CAN-bus technology |

Height: 2217 mm | Hydraulic valve: Rexroth, Parker, Mico | 5.7” color display |

Ground clearance: 286 mm | Fuel tank capacity | 3 modular design |

Dump height: 1826 mm | Hydraulic oil tank: 230L | |

Steering angle: ±42.5° | Fuel tank: 210L | Trouble alarm |

Inner turning radius: 2814mm | Cooler: engine, transmission oil, hydraulic oil | Self-diagnosis |

Out turning radius: 5809mm | Data log download | |

FL04 ——4MT 2m³ Diesel power

FL04 is a 4 ton diesel LHD specially designed for small underground metal mines, it has a compact structure and smaller turning radius, especially suitable for narrow roadways. The FL04 is equipped with a 89KW CUMMINS Engine QSB4.5 with 89KW rated power, which has strong power, strong Breakout force and low failure rate due to high power reserve. Steering operation control adopts hydraulic handle, convenient and comfortable operation. The braking system adopts Posi-Stop spring brake and hydraulic release brake, and the safety is better. The FL04 highland type LHD is equipped with Deutz BF6L914 engine with power of 112KW. The power of the engine is 71.5KW at an altitude of 4500 meters, which meets the requirements of high altitude operation.

Specification

Performance | Engine | Drivetrain system |

St bucket capacity: 2m³ | Model: CUMMINS QSB4.5 | Torque converter: DANA C270 |

Rated payload: 4,000 kg | Power: 97KW @ 2300rpm | Transmission: DANA R32000 |

Operating weight: 13100 kg | Torque: 572Nm @ 1500 rpm | Axle: DANA 14D |

Breakout force: 110 KN | Type: Electric injection, water cooled, two stage filtration, catalytic purifier | Brake: Posi-Stop wheel brake |

Traction force: 130 KN | Tire model: 12.00-24 | |

Others | Cabin | Option |

Manual central lubrication system fire extinguisher | Joystick control | lincoln automatic lubrication system |

Boom bolt/ hinge bolt/ reverse alarm | FOPS/ ROPS Certified | Ansul auto fire suppression system |

Fire Extinguisher | Steering and working hydraulic pilot control | DEUTZ air cooled engine |

Electronically controlled shift, hydraulic throttle control | ||

LED front and rear lights | ||

Dimension | Hydraulic system | Electric system |

Length: 7187 mm | Hydraulic pump: Parker gear pump | Voltage: 24V |

Width: 1789 mm(cabin included) | Hydraulic valve: Rexroth, Parker, Mico | Component: Bosch, Tyco, Deutsch |

Height: 2170 mm | Hydraulic oil tank capacity: 144L | Travel speed (Full load) |

Ground clearance: 252 mm | Fuel tank capacity:148L | 1st gear: 5.2 km/h |

Dump height: 1732 mm | 2nd gear: 9.6 km/h | |

Steering angle: ±40° | Bucket motion time | 3rd gear: 16 km/h |

Inner turning radius: 2659mm | Lifting: 4.1s | 4th gear: 26.7km/h |

Out turning radius: 4937mm | Dumping: 3.2s | |

FL04 ——4MT 2m³ Diesel power

FL04 is a 4 ton diesel LHD specially designed for small underground metal mines, it has a compact structure and smaller turning radius, especially suitable for narrow roadways. The FL04 is equipped with a 89KW CUMMINS Engine QSB4.5 with 89KW rated power, which has strong power, strong Breakout force and low failure rate due to high power reserve. Steering operation control adopts hydraulic handle, convenient and comfortable operation. The braking system adopts Posi-Stop spring brake and hydraulic release brake, and the safety is better. The FL04 highland type LHD is equipped with Deutz BF6L914 engine with power of 112KW. The power of the engine is 71.5KW at an altitude of 4500 meters, which meets the requirements of high altitude operation.

Specification

Performance | Engine | Drivetrain system |

St bucket capacity: 2m³ | Model: CUMMINS QSB4.5 | Torque converter: DANA C270 |

Rated payload: 4,000 kg | Power: 97KW @ 2300rpm | Transmission: DANA R32000 |

Operating weight: 13100 kg | Torque: 572Nm @ 1500 rpm | Axle: DANA 14D |

Breakout force: 110 KN | Type: Electric injection, water cooled, two stage filtration, catalytic purifier | Brake: Posi-Stop wheel brake |

Traction force: 130 KN | Tire model: 12.00-24 | |

Others | Cabin | Option |

Manual central lubrication system fire extinguisher | Joystick control | lincoln automatic lubrication system |

Boom bolt/ hinge bolt/ reverse alarm | FOPS/ ROPS Certified | Ansul auto fire suppression system |

Fire Extinguisher | Steering and working hydraulic pilot control | DEUTZ air cooled engine |

Electronically controlled shift, hydraulic throttle control | ||

LED front and rear lights | ||

Dimension | Hydraulic system | Electric system |

Length: 7187 mm | Hydraulic pump: Parker gear pump | Voltage: 24V |

Width: 1789 mm(cabin included) | Hydraulic valve: Rexroth, Parker, Mico | Component: Bosch, Tyco, Deutsch |

Height: 2170 mm | Hydraulic oil tank capacity: 144L | Travel speed (Full load) |

Ground clearance: 252 mm | Fuel tank capacity:148L | 1st gear: 5.2 km/h |

Dump height: 1732 mm | 2nd gear: 9.6 km/h | |

Steering angle: ±40° | Bucket motion time | 3rd gear: 16 km/h |

Inner turning radius: 2659mm | Lifting: 4.1s | 4th gear: 26.7km/h |

Out turning radius: 4937mm | Dumping: 3.2s | |