ATLAS 5575074300 for ST1030 in Stock

DANA 12.1MHR32369-601 P/N293054/12.1MHR32369-631 P/N4263951

Overview Of Atlas Copco Epiroc Scooptram

ST1030 Replacement Parts

The Atlas Copco Epiroc Scooptram ST1030 Replacement Parts are designed to meet the rigorous demands of underground mining operations. These parts are engineered with precision and manufactured to the highest standards, ensuring exceptional durability, reliability, and performance in challenging environments. As a trusted supplier in the global mining industry, Hambition Mining offers a complete range of replacement components that extend the life and efficiency of your Scooptram ST1030 loader.

Whether you need hydraulic systems, transmission parts, axles, or engines, Hambition provides cost-effective solutions tailored to your operational needs. Our components are thoroughly tested to ensure compatibility with industry standards, delivering peak performance and safety for your equipment.

Features Of Atlas Copco Epiroc Scooptram ST1030 Replacement Parts

OEM Design: The replacement parts are designed to match the original equipment specifications, ensuring a perfect fit and optimal compatibility with the Scooptram ST1030 loader.

High-Performance Materials: Manufactured using premium-grade materials like heavy-duty steel, aluminum, and advanced alloys to withstand extreme mining conditions.

Precision Engineering: All parts adhere to advanced engineering standards, providing maximum efficiency and minimizing downtime.

Global Adaptability: Suitable for various underground mining environments, including gold, copper, and polymetallic mining operations.

Wide Application: These parts enhance the efficiency of hydraulic systems, torque converters, transmissions, and axles, ensuring smooth and uninterrupted operation.

Product Quality Control

Hambition Mining prioritizes quality control at every stage of the manufacturing process. Our rigorous inspection procedures ensure that each component meets the highest standards of reliability and safety.

Quality Control Measures Of

Atlas Copco Epiroc Scooptram ST1030 Replacement Parts

Material Testing: High-quality raw materials are selected and tested for stress, heat resistance, and durability.

Three-Stage Testing:

Data Test: Measurement calibration and size precision.

Operational Test: Functionality checks for joysticks, buttons, and hydraulic systems.

Fault Detection: Sealing tests and system alerts for potential issues.

ISO and CE Certification: All products comply with ISO1217, IS02151:2004, and CE certification, ensuring adherence to global standards.

Applications Of Atlas Copco Epiroc Scooptram ST1030 Replacement Parts

The Atlas Copco Epiroc Scooptram ST1030 Replacement Parts are essential for maintaining and optimizing the performance of underground loaders. These components are specifically designed to:

Enhance machine efficiency in narrow tunneling operations.

Provide reliable support in heavy-duty load-hauling tasks.

Reduce downtime and improve productivity in gold, copper, and polymetallic mining projects.

Product Production Process

The production of replacement parts for the Scooptram ST1030 involves advanced manufacturing techniques and quality assurance protocols:

Design and Prototyping: Engineers design parts using CAD software, ensuring precise specifications.

Material Selection: High-grade metals and alloys are sourced for maximum durability.

Precision Manufacturing: CNC machining and automated assembly guarantee consistency and accuracy.

Testing and Inspection: Each part undergoes mechanical, operational, and stress testing to ensure reliability in demanding conditions.

Packaging and Delivery: Secure packaging prevents damage during transit, ensuring the parts arrive in perfect condition.

Service and Support

Hambition Mining offers unparalleled service and support to ensure that your mining operations run smoothly.

Our comprehensive services include:

Pre-Sales Service

24/7 consultation with professional engineers to assess your project requirements.

Customized solutions based on mining conditions, ore type, and capacity demands.

In-Service Support

On-site engineers to guide installation, adjustment, and initial operations.

Comprehensive training for maintenance teams, covering operational methods and spare parts management.

After-Sales Service

One-year warranty on all replacement parts.

Regular follow-ups via phone, email, or online support.

Quick replacement of defective parts and guidance for repairs.

Why Choose Us

Hambition Mining stands out as a leading provider of underground mining equipment and spare parts due to our commitment to quality and customer satisfaction.

Here’s why you should choose us:

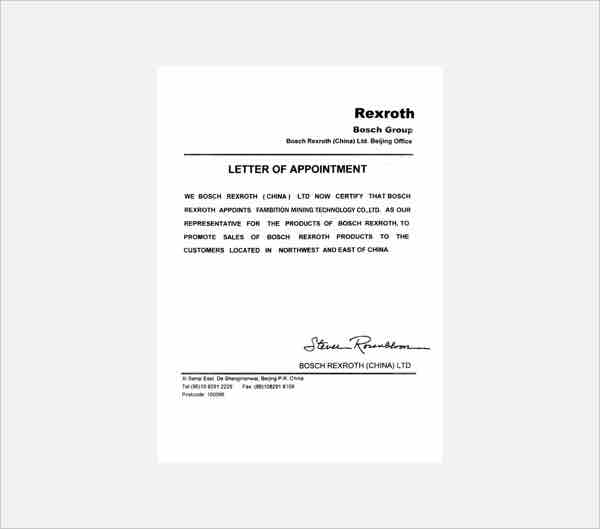

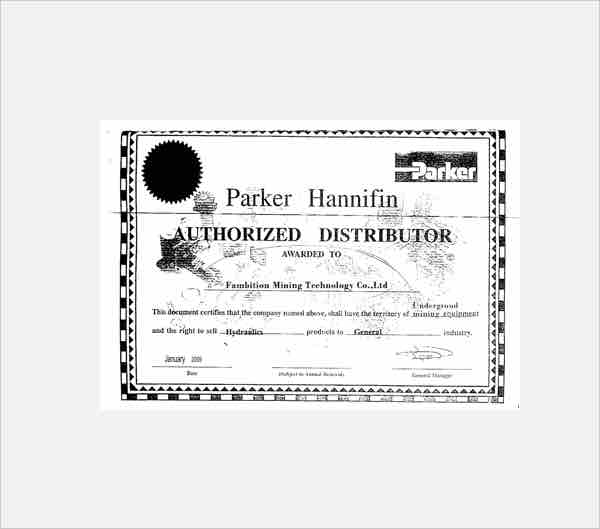

Awards & Certifications

Keep in touch with us

If you have any questions or requirements, please feel free to contact our customer service team.

Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+86-532-85768537

E-mail:info@hambition.com